Advanced Metrology Accelerates Performance for Sportscar Race Team

From Tooling & Production – Strategies For Large Metalworking Plants

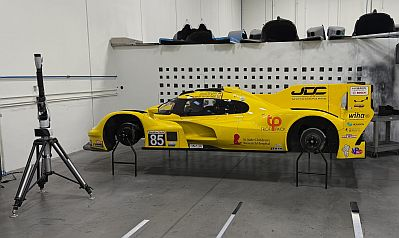

In motorsports, where aerodynamic efficiency and mechanical accuracy can mean the difference between a podium finish and a mid-pack result, precision isn’t a luxury — it’s a necessity. As Brian Winters, Product Manager at Hexagon Manufacturing Intelligence, writes, Minnesota-based JDC-Miller MotorSports understands this better than most.

Competing in the top-tier GTP class of the IMSA WeatherTech Sportscar Championship with the Porsche 963, JDC-Miller Motorsports is embracing advanced metrology to optimize vehicle performance.

Founded in 1969, IMSA is the premier sportscar racing series in North America, hosting such iconic races as the Rolex 24 at Daytona and the 12 Hours of Sebring. Both are races that drivers around the world aspire to have on their resume. Manufacturers such as Porsche, BMW, Acura, and Cadillac are heavily involved. The GTP class features highly advanced hybrid drive systems as well as other cutting-edge technologies.

Through a new partnership with Hexagon’s Manufacturing Intelligence division, JDC-Miller is integrating high-precision measurement technology into its workflow to enhance consistency, compliance, and overall race-day efficiency.

Precision and Compliance: The Foundations of Performance

Racing in IMSA’s highly competitive, sometimes rough and tumble, GTP class means operating within strict regulatory tolerances — teams are allowed only a 3mm deviation from factory-body specifications. These tight margins leave little room for error, making precise measurement a critical component of pre-race preparation.

Before partnering with Hexagon, JDC-Miller relied on jigs and manual measurements, a process that was both time-consuming and prone to minor inaccuracies. The introduction of advanced metrology tools has significantly reduced the margin for error, ensuring compliance from the moment the car comes off the truck.

“Before, we were using jigs that we built ourselves — rudimentary measurements that got the job done but left room for error,” said John Church, Managing Partner at JDC-Miller MotorSports. “With Hexagon’s scanning technology, we’ve eliminated that uncertainty. We’re now able to establish a precise baseline for the car before we even get to the track, which means less troubleshooting and more focus on performance.”

Unlocking Performance with Advanced Scanning

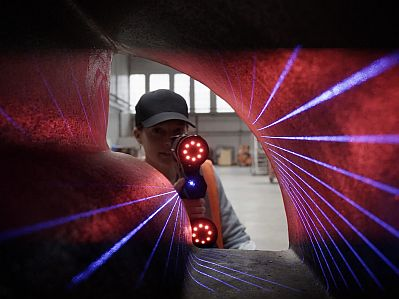

At the heart of the partnership is Hexagon’s cutting-edge 3D portable scanner, MARVELSCAN, which captures millions of data points in seconds, creating highly detailed digital models of the vehicle’s exterior and components. This allows engineers to quickly identify deviations from optimal specifications, enabling them to make necessary adjustments before the car takes to the track.

MarvelScan Tracker-Free and Marker-Free Portable 3D Laser Scanner

The scanner’s advanced features — such as edge detection, built-in photogrammetry, the ability to scan reflective surfaces, and scanning without targets — make it particularly well-suited to the complex geometries, large objects and lightweight composites used in motorsports.

“With all the different curves and surfaces on these cars, it’s nearly impossible to measure accurately using traditional methods,” Church said. “MARVELSCAN changes that. We can scan the car before and after each race weekend and see exactly what’s moved, what’s changed, and what needs adjustment. That level of detail helps us fine-tune everything — from body panel fitment to suspension alignment.”

Beyond compliance, metrology technology enables JDC-Miller to optimize aerodynamics and structural integrity. By catching even the smallest inconsistencies, the team can make data-driven adjustments that enhance overall performance. Whether it’s verifying the precision of newly installed components or ensuring a perfect fit between subassemblies, accurate measurement reduces repair time and improves reliability.

From Workshop to Trackside Advantage

JDC-Miller is now incorporating metrology into its standard workflow, scanning the cars before each race weekend and after any incidents to assess structural integrity. By comparing pre- and post-race scans, engineers can quickly determine whether components have shifted or sustained damage, allowing for faster repairs and more consistent performance. This proactive approach not only saves time during trackside inspections but also minimizes the risk of undetected misalignments that could hinder race results.

“There’s never enough time at the track,” Church explained. “The last thing we want to do during a race weekend is double-check things we should have already validated at the shop. With metrology, we know exactly what we’re working with before we even roll the car off the truck.”

The benefits were on full display during the grueling Rolex 24 At Daytona.

Over 24 hours, JDC-Miller executed 32 pit stops, fueling the car and changing 21 sets of tires — each stop averaging under a minute. “We compete with all the other teams in the pits as well as on the track. The goal is to minimize the amount of time the car is stopped. At Daytona, we were among the very best at quick and efficient stops,” Church said. “That level of efficiency is a game-changer. Consistency in setup means fewer surprises, and fewer surprises mean more confidence in the car for the driver and the crew.”

Bridging Technology and Expertise

To ensure seamless adoption of this technology, JDC-Miller is working with Productivity Quality, Inc. (PQI), a regional metrology expert providing hands-on training and ongoing support. PQI’s expertise is helping the team master the scanning process and best practices in measurement analysis. Over time, JDC-Miller aims to take full ownership of the technology, using remote support from PQI as needed.

“When we first started looking for a scanning partner, we knew we needed more than just the best equipment — we needed a team that could help us leverage the technology and integrate it into our workflow,” said Roger Johnson, Partner Relations at JDC-Miller MotorSports. “Hexagon and PQI have been great in that regard. The equipment is user-friendly, and with PQI’s guidance, we are quickly gaining proficiency. The team is already identifying new opportunities to find uses for the technology that go far beyond what was initially anticipated.”

This collaboration highlights the growing role of metrology in motorsports, where even the smallest deviations can impact performance. By incorporating precise measurements into their workflow, JDC-Miller is positioning itself for greater consistency, faster repairs, and more predictable performance outcomes.

Looking Ahead: Innovation Beyond Compliance

As the partnership evolves, JDC-Miller is exploring additional applications for metrology beyond regulatory compliance and damage assessment. This includes creating digital molds of body panels and subassemblies for rapid repairs, as well as using CAD-to-part comparisons to prevent rework during assembly. By leveraging accurate data throughout the vehicle lifecycle, the team aims to streamline maintenance processes and improve long-term reliability.

“We’ve barely scratched the surface of what this technology can do,” Church said. “We’re looking at scanning body panels to create digital molds for repairs, analyzing subassemblies before installation to prevent rework, and even using real-time data to refine our performance strategy. The possibilities are endless.”

Want more information? Click below.