JDC-Miller MotorSports Announces Dynamic Young Lineup for the 2026 Rolex 24 at Daytona

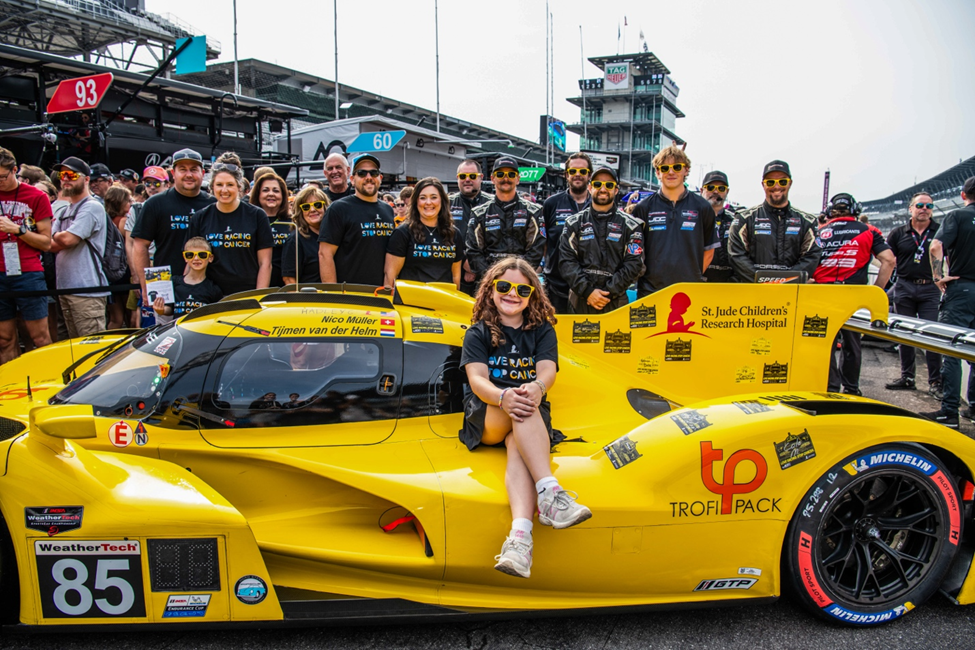

SAVAGE, MN (January 8, 2026) – JDC-Miller MotorSports is proud to announce its driver lineup for the 81st running of the Rolex 24 at Daytona. The team’s No. 85 Porsche 963 will be piloted by a high-octane trio of rising, young, but experienced stars: Tijmen van der Helm, Nico Pino, and Kaylen Frederick.

Tijmen van der Helm (Netherlands) returns to the team for his fourth straight season in the IMSA WeatherTech Championship GTP class. As a key part of the JDC-Miller program, van der Helm brings valuable experience with the Porsche 963 platform. The 21-year-old has 23 starts in the JDC-Miller MotorSports Porsche 963. This is his fourth Rolex 24 Hours of Daytona with the team, ith best finishes of 6th in both 2024 and 2025.

“I am excited to continue my journey with JDC-Miller MotorSports,” said van der Helm. We’ve made massive strides in understanding this car over the past three years, and starting the 2026 season with such a talented team around us gives us a real chance at the podium.”

Joining van der Helm is Nico Pino, from Santiago, Chile, who joins JDC-Miller MotorSports after an impressive tenure in both the FIA World Endurance Championship and IMSA’s WeatherTech SportsCar Championship. Now 20 years old, Pino moved from carts to open-wheel cars at age 13. In 2021, he became the youngest driver ever to compete in the European Le Mans Series (ELMS) at just 16. At the 24 Hours of Le Mans in 2023, he earned a notable third-place finish in the highly competitive LMP2 class. In 2025, he drove a Porsche 963 eleven times in both IMSA and WEC. Pino also made headlines driving the JDC-Miller MotorSports 963 during the IMSA November 2025 tests at Daytona, setting the fastest time overall in the fourth session and finishing second overall for the test. This will be his 5th Rolex 24 at Daytona.

“Joining a team with the history and passion of JDC-Miller MotorSports is a major milestone,” Pino noted. “It’s incredible to be back in the 963 for 2026, especially with a team like JDC-Miller MotorSports. I’m ready to push for a watch at Daytona.”

Completing the roster is American standout, 23-year-old Kaylen Frederick. Frederick has extensive experience in Formula 3. He dominated the 2020 BRDC British Formula 3 Championship and became the first American to win that prestigious title. Frederick will be competing in the Michelin Endurance Cup races with JDC-Miller MotorSports and is looking to expand on that program as the season progresses.

“It is a bit humbling to begin my sports car career driving for a top team like JDC-Miller MotorSports, in a car like the Porsche 963, and at one of the biggest races of the year, the Rolex 24 at Daytona. I started my national karting career at the kart track in the Daytona infield, so it seems fitting that I am now starting my endurance racing career at the same prestigious venue. I am very much up to the challenge and know the team will get me up to speed quickly. I’m looking forward to a good result.”

“We are incredibly excited about this lineup, said John Church, Managing Partner of JDC-Miller MotorSports. In Tijmen, Nico, and Kaylen, we have three of the brightest young talents in the sport. They are fast, disciplined, and hungry to succeed in a 24-hour race like the Rolex 24 at Daytona. We have finished 6th here over the past two years, and with this lineup, we are confident we can reach the podium with the goal of taking the top step.”